1. Panagsukimat ed istruktura

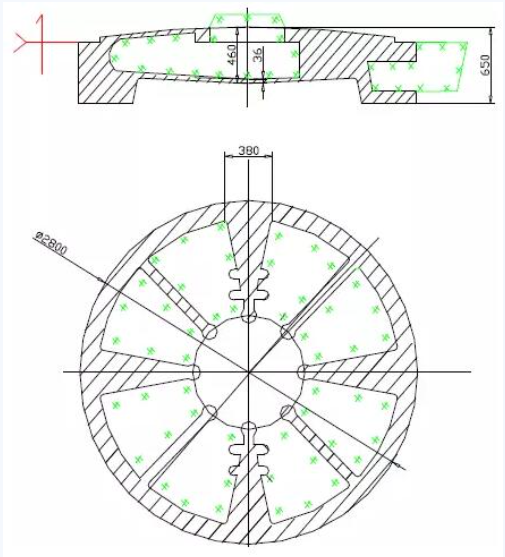

(1) Sayabalbula na kulibangbangwalay pabilog ya singa cake ya istruktura, say loob ya abut et akakonekta tan susuportaan na 8 ya pampabiskeg na taglang, say tagey ya Φ620 ya abut et mikokonektaan ed loob ya abut, tan say arum ninbalbulaet sarado, say sand core et mairap ya ayosen tan mainomay ya naderal. Parehon say tambutso tan say panlinis ed loob na abut so mangitarok na baleg iran kairapan, a singa nanengneng ed Figure 1.

Say kapal na dingding na saray castings et manduruma, say sankatageyan ya kapal na dingding et onabot ed 380mm, tan say sankaabebaan ya kapal na dingding et 36mm labat. No say casting et malet, baleg so pandumaan na temperatura, tan say ag-inkapareho na shrinkage et mainomay ya mamawala na shrinkage cavities tan shrinkage porosity defects, ya pansengegan na onlelereg ya danum ed hydraulic test.

2. Desinyo na proseso:

(1) Say parting surface et nanengneng ed Figure 1. Iyan so sampot ya walay abot to ed tagey a kahon, manggawa na interon sand core ed pegley a abot, tan pabalegen so core head ya duga pian napagaan so pangipeket na sand core tan say igalaw na sand core no say kahon et ibaliktad. Malet, say karukey na cantilever core head na duaran blind holes ed gilig et mas andukey nen say karukey na hole, kanian say sentro na grabidad na interon sand core et aka-bias ed gilig na core head pian naseguro ya say sand core et akapeket tan malet.

Say semi-closed pouring system so inadapta, ∑F ed loob: ∑F horizontal: ∑F diretso=1:1.5:1.3, say sprue et manguusar na ceramic tube ya walay inner diameter to ya Φ120, tan duaran piraso na 200×100×40mm ya refractory bricks so inyan ed leksab pian ag-ontutunaw so bakal sand mold, sakey a 150×150×40 foam ceramic filter so inyan ed leksab na runner, tan 12 ceramic tubes ya walay inner diameter to ya Φ30 so inusar parad inner runner pian makakonekta ya parepareho ed leksab na casting diad panamegley na water collection tank ed leksab na filter pian makaporma na bottom pouring scheme a singa nanengneng ed Figure 2

(3) Mangiyan na 14 ∮20 ya cavity air holes ed tagey na hulma, mangiyan na Φ200 ya sand core vent hole ed pegley na core head, mangiyan na ambetel ya bakal ed makapal tan angkakabaleg iran parte pian naseguro so balansin panagpalet na casting, tan usaren so graphitization expansion principle pian kanselaen so proseso na feeding riser ya inusar pian napaaligwas so ani. Say kabaleg na sand box et 3600×3600×1000/600mm, tan sikatoy inwelding na 25mm ya kapal na steel plate pian naseguro so magenap ya biskeg tan inkapekder, a singa nanengneng ed Figure 3.

3. Kontrol ed proseso

(1) Panagmodelo: Antis ya manmodelo, mangusar na Φ50×50mm ya estandarten sample pian nasubok so biskeg na panag-ipit na resin sand ≥ 3.5MPa, tan i-tighten so cold iron tan say runner pian naseguro ya say sand mold et walaan na magenap ya biskeg pian na-offset so graphite ya napapawala no say tinunaw ya iron et onlereg, tan ag-ontutunaw so iron runner part ed andukey a panaon pian pansengegan na sand washing.

Say panggawa na utek: Say utek na buer et naapag ed 8 a pantatalosan a parte na 8 a pampabiskeg a tagiliran, ya akakonekta ed pegley a abot. Anggapoy arum ya parte na suporta tan tambutso likud ed pegley ya core head. No ag naayos so sand core tan Exhaust, say sand core displacement tan saray abut na dagem et ompatnag kayari na pangibubo. Lapud baleg so interon lawak na buer, naapag itan ed waloran parte. Kaukolan ya magenap so biskeg tan inkapekder to pian naseguro ya ag naderal so buer kayari na ipaway na amag, tan ag naderal kayari na pangibubo. Nagagawa so deformation, pian naseguro so pareparehon kapal na dingding na casting. Lapud saya, nanggawa kami na espisyal ya core bone, tan insinger mi itan ed core bone panamegley na lubir na bentilasyon pian naala so exhaust gas manlapud core head pian naseguro so inka-compact na sand mold legan ya gagawaen so core. Singa nanengneng ed Figure 4.

(4) Closing box: Lapud mairap ya linisan so buer ed loob na butterfly valve, say interon buer et pintaan na duaran layer na pintura, say unonan layer et pintaan na alcohol-based zirconium paint (Baume degree 45-55), tan say unonan layer et pintaan tan poolan. Kayari na pamamaga, pintaan so komaduan layer na alcohol-based magnesium paint (Baume degree 35-45) pian ag-onpeket so casting ed buer tan ag-on-sinter, ya ag nayarin linisan. Say core head part et akabitin ed Φ200 steel pipe na manunan istruktura na core bone ya walay taloran M25 screws, ya akapeket tan akakandado ed upper mold sand box ya walay screw caps tan in-check no parepareho so kapal na dingding na kada parte.

4. Proseso na panagtunaw tan panagbubo

(1) Mangusar na Benxi low-P, S, Ti high-quality Q14/16# pig iron, tan idagdag itan ed ratio ya 40%~60%; saray trace elements a singa say P, S, Ti, Cr, Pb, tan arum nira et malet ya kontrolado ed scrap steel, tan anggapoy rust tan oil ya naabuloyan, say addition ratio et 25%~40%; say nipawil ya karga et kaukolan ya linisan panamegley na shot blasting antis ya usaren pian naseguro so kalinisan na karga.

(2) Say manunan kabiangan na panangontrol kayari na hurnoan: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (residual): 0.035% ~0.05%, diad silong na spherization, say ensuperization na premisasyon, say ensuperization na premisation say abeban limitasyon na Mg (residual) et nepeg ya inumen anggad posible.

(3) Spheroidization inoculation treatment: low-magnesium tan low-rare-earth spheroidizers so uusaren, tan say addition ratio et 1.0%~1.2%. Say tradisyonal a paraan na panag-flush na panagtambal na spheroidization, 0.15% na one-time inoculation so nasakbongan ed nodulizer diad leksab na pakete, tan say spheroidization et asumpal la. Say slag et i-subcontrata parad segundaryon inokulasyon ya 0.35%, tan say flow inoculation ya 0.15% et gawaen legan na panagbubo.

(5) Inadapta so proseso na maples ya panagbubo ed abeban temperatura, say temperatura na panagbubo et 1320°C~1340°C, tan say panaon na panagbubo et 70~80s. Say tinunaw ya bakal et ag nayarin naandi legan ya ibububo, tan say sprue cup et lanang ya napno pian ag makaloob so gas tan saray inklusyon ed molde panamegley na runner. lubok.

5. Resulta na casting test

(1) Suboken so biskeg na panag-awit na cast test block: 485MPa, elongation: 15%, Brinell hardness HB187.

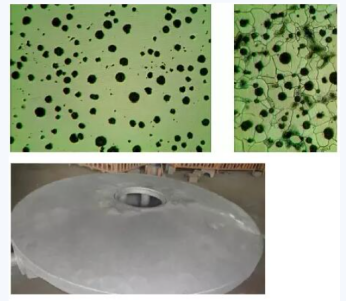

(2) Say spheroidization rate et 95%, say kabaleg na graphite et grade 6, tan say pearlite et 35%. Say metallographic structure et nanengneng ed Figure 5.

(3) Anggapoy narekord ya depekto ed UT tan MT secondary flaw detection na saray importantin parte.

(4) Say itsura to et patatdang tan makinis (nengnengen so Figure 6), ya anggapoy depekto ed panag-cast a singa say sand inclusions, slag inclusions, cold shuts, tan arum ni, say kapal na dingding et parepareho, tan saray sukat to et makatunongan ed saray kakaukolanen na saray drowing.

(6) Say 20kg/cm2 hydraulic pressure test kayari na panagproseso et anggapoy anengneng ya leakage

6. Konklusyon

Unong ed saray katangian na sayan butterfly valve, say problema na ag-establi tan mainomay ya depormasyon na baleg a sand core ed pegley tan mairap a panaglinis na sand et nasolbar diad pangidanet ed desinyo na plano na proseso, say produksyon tan pangapiger ed sand core tan say pangusar na zirconium-based coatings. Say pangiletneg na saray abot na bentilasyon et mamapaliis ed posibilidad na saray pores ed saray casting. Manlapud furnace charge control tan runner system, foam ceramic filter screen tan ceramic ingate technology so uusaren pian naseguro so inkapuro na tinunaw ya bakal. Kayari na dakel ya inoculation treatments, say metallographic structure na castings tan nanduruman Say komprehensibon performance et akasabi lad estandarten kakaukolanen na saray kustomer

NanlapudTianjin Tanggu Water-seal valve Co.,ltd. Balbula na kulibangbang, gate valve, Y-strainer, wafer dual plate check valvepanaggawa.

Oras na post: Apr-29-2023